Services

Services

Our core competence is machining, CNC turning/milling in all designs and materials. In addition, forged parts from our Plant II and castings from external plants are mechanically reworked.

In order to round off our product portfolio and to ensure constant customer satisfaction, we also carry out external work. Depending on requirements, external production processes are outsourced to selected partner companies and monitored by our QA.

External work

Casting:

Gray cast iron, iron casting, investment casting, die casting, ductile iron, aluminum casting.

Stamping:

Stamped and deep-drawn parts according to drawings, bent parts, disc springs according to drawings or DIN 2093.

Complete assemblies:

Welded parts according to drawing, assembly parts

Eroding:

Die sinking, wire eroding

Hardening, thermochemical and partial processes:

Induction hardening, quenching and tempering, case hardening, carburizing, nitriding, carbonitriding.

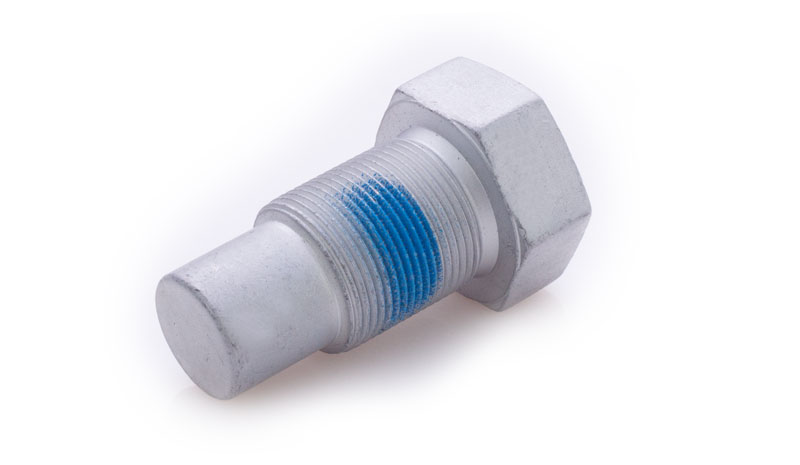

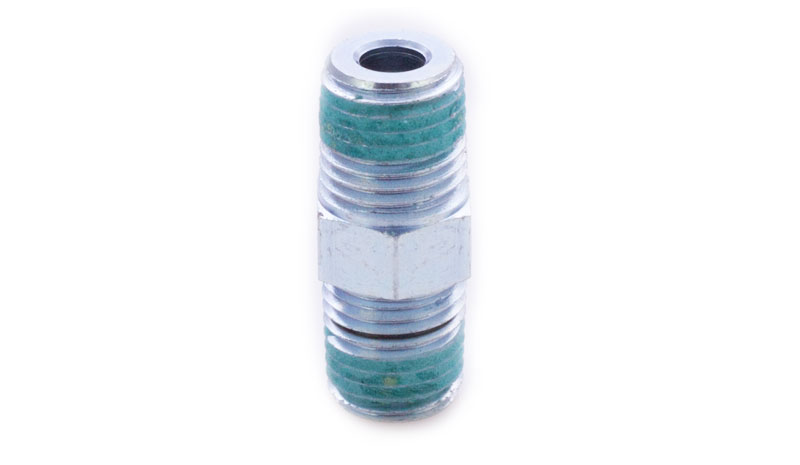

Surface corrosion protection systems, rack and barrel products:

Zinc flake coatings, galv. Cr-VI-free zinc coatings, Cr-VI-free passivations, chromating, zinc phosphating, hot-dip galvanizing.